Blog

Total

56

2024.09.27

Maximizing Valve Performance and Ensuring Safety: Unlocking the Power of Enhanced Packing Techniques

Valve stem packing is crucial for optimizing performance and ensuring safety in industries like oil & gas and chemical processing. Enhanced packing techniques using advanced materials and designs prevent leaks, reduce friction, and extend valve lifespan. This article highlights the common challenges of traditional packing, the benefits of modern packing methods, and best practices for selecting and maintaining the right packing materials. By implementing these innovations, industries can improve operational efficiency, reduce environmental risks, and ensure regulatory compliance.

2024.09.20

The valve industry, critical to sectors like oil & gas and chemical processing, faces challenges including corrosion, high-pressure conditions, and quality control issues. Strategies like using advanced materials, adopting predictive maintenance, and integrating digital technologies are essential for optimizing valve performance. Embracing automation and smart systems will help address these challenges and unlock long-term efficiency and reliability.

2024.09.13

The guide discusses commonly used materials such as stainless steel, brass, Monel, carbon steel, Hastelloy, plastics, and titanium, outlining their strengths, applications, and limitations. Factors like corrosion resistance, temperature resistance, pressure handling, and media compatibility are explored to help readers make informed decisions. Case studies provide real-world examples of how proper material selection can significantly enhance valve performance and reliability. The article concludes by emphasizing the importance of certified materials and long-term cost considerations in maintaining system safety and efficiency.

2024.09.06

This article explores how automation and technological innovations are transforming the flow control industry. Automation is now essential for industrial processes, enabling real-time monitoring, precise adjustments, and improved operational efficiency. Smart technologies like AI, machine learning, and IoT are driving this shift by integrating smart valves, sensors, and control systems that gather data for predictive maintenance. Additionally, as industries expand globally, companies face new challenges such as regulatory requirements, environmental conditions, and a growing demand for sustainable solutions. Automation is being applied across sectors like oil & gas, water treatment, chemical processing, and food & beverage, offering benefits such as reduced costs, enhanced precision, and environmental efficiency. However, there are challenges to adopting automation, including high initial costs and infrastructure compatibility. The article concludes by highlighting future trends such as AI-powered systems, 5G connectivity, and Industry 4.0 technologies, which will shape the future of flow control. Businesses that embrace these innovations will lead the next era of automation in industrial operations.

2024.08.30

The next generation of severe service valves is transforming industrial applications across sectors like oil & gas, chemical processing, and power generation. These advanced valves are engineered to withstand extreme temperatures, pressures, and corrosive environments while offering enhanced durability, reliability, and control capabilities. With innovations like safety valves, cryogenic valves, and stainless steel control valves, they are pushing the boundaries of efficiency and sustainability in critical industrial processes. By integrating cutting-edge materials and digital technologies, industries can reduce downtime, improve safety, and optimize operational efficiency. As the industrial landscape evolves, severe service valves are poised to play a vital role in driving long-term growth and competitiveness.

2024.08.23

The valve manufacturing industry is evolving to meet modern industrial demands, driven by trends like enhanced reliability, automation, and environmental concerns. Significant advancements have been made in the areas of safety valves, cryogenic valves, and stainless steel control valves, each designed to enhance safety, durability, and performance in extreme environments. These innovations are not only shaping the future of industrial processes by improving efficiency and reliability but also boosting global competitiveness by enabling industries to comply with stricter safety and environmental regulations while optimizing operational productivity.

2024.08.16

This article explores the critical role of pressure relief valves (PRVs) in ensuring safety and efficiency in industrial operations, particularly in boiler systems. It highlights the importance of selecting the right PRV for different applications, including the distinction between ASME I and ASME VIII valves for boilers. Proper PRV selection, installation, and maintenance are essential for preventing catastrophic failures, safeguarding personnel, and maintaining the continuity of industrial processes. Adhering to regulatory standards and best practices in PRV management ensures the safe and efficient operation of high-pressure systems, ultimately contributing to the overall productivity and profitability of industrial operations.

2024.08.09

The article delves into the critical role that valve technology plays across various industries, including manufacturing, energy, water treatment, and more. It emphasizes the importance of selecting the right valve type—such as gate valves, ball valves, butterfly valves, or check valves—based on specific operational requirements. The article further explores factors to consider when choosing valve technology, such as operating conditions, material construction, flow control, and system integration challenges. Additionally, it highlights emerging trends in valve technology, like smart valves and energy-efficient designs, while also providing insights into the cost-effectiveness of different valve options. The piece concludes with practical maintenance and troubleshooting tips, emphasizing the need for regular inspections and proactive measures to ensure long-term reliability and efficiency.

2024.08.02

Severe service valves are essential components in various industries due to their ability to operate under extreme conditions such as high temperatures, high pressures, corrosive environments, and abrasive materials. These specialized valves ensure consistent performance, durability, and safety, making them vital in sectors like oil and gas, power generation, chemical processing, and mining. The article explores the unique features, benefits, and real-world applications of severe service valves, highlighting their importance in maintaining operational efficiency and safety. It also provides insights into key characteristics, types, and factors to consider when selecting these valves for specific applications.

2024.07.26

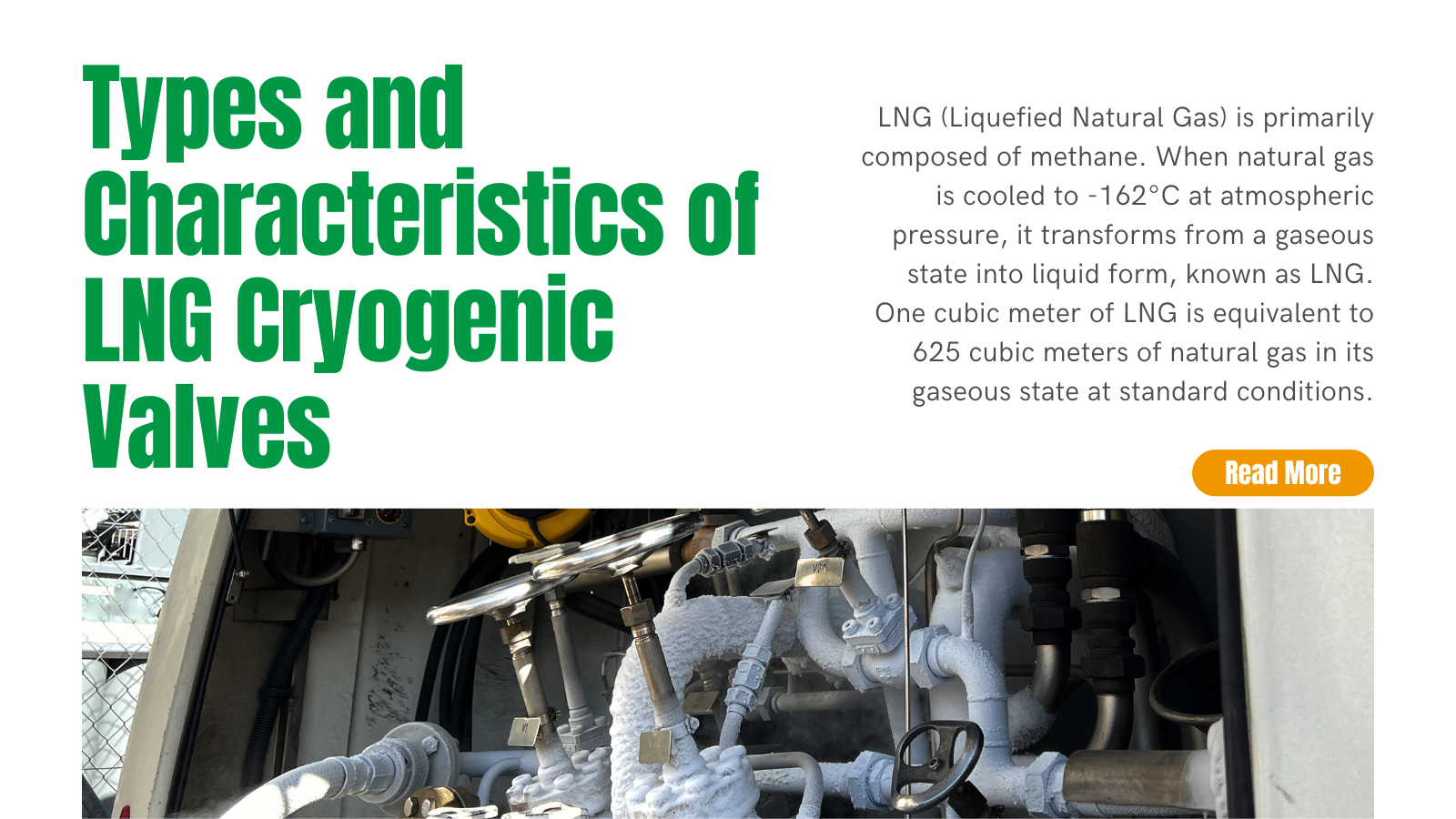

LNG (Liquefied Natural Gas) is primarily composed of methane. When natural gas is cooled to -162°C at atmospheric pressure, it transforms from a gaseous state into liquid form, known as LNG. One cubic meter of LNG is equivalent to 625 cubic meters of natural gas in its gaseous state at standard conditions. This significant volume reduction makes the storage and transportation of LNG more efficient and cost-effective.

2024.07.19

Cryogenic valves are critical for managing ultra-low temperature gases and liquids in various industries. Key considerations for selecting the right valve include temperature range, material selection, design, leakage prevention, and industry certifications. Making informed choices ensures safety, efficiency, and reliability in cryogenic operations.

2024.07.12

The liquefied natural gas (LNG) sector is poised for significant growth, creating a wealth of opportunities for valve manufacturers. As global demand for natural gas rises, the LNG market is expanding rapidly, with projections showing substantial increases in LNG conversions and exports through 2040.

2024.07.05

We underscores that diligent maintenance of seals and gaskets is essential for ensuring the longevity and optimal performance of mechanical systems. By following the outlined practices, operators can prevent costly repairs, improve system efficiency, and maintain reliable machinery operations.

2024.06.28

The article highlights the importance of reducing emissions for sustainability, the challenges faced in emissions control, and the innovative technologies being developed to address these issues. The article also discusses the role of government regulations, industry collaboration, and standards in driving emissions control efforts.

2024.06.21

The article highlights best practices for monitoring and maintaining emission-control valves, essential for regulatory compliance and environmental sustainability. It emphasizes the importance of proper maintenance to prevent leaks, malfunctions, and non-compliance issues, which can harm the environment and a company's reputation. The article details various monitoring techniques, including real-time and predictive maintenance, and outlines effective maintenance strategies such as scheduled and condition-based maintenance. It also underscores the need for specialized training and certification for personnel handling these valves. Common issues like leakage, blockages, and corrosion are addressed, along with the necessary tools and equipment for effective maintenance. Real-world case studies demonstrate the successful implementation of monitoring programs, showcasing cost savings and improved efficiency. It concludes with cost-saving strategies and emphasizes the future importance of continuous innovation, collaboration, and adherence to evolving regulatory standards.

2024.06.14

The article highlights the crucial role of valve technology in minimizing emissions and promoting sustainability across industries. The article covers different types of valve-related emissions, the regulatory landscape, and the importance of compliance. It explores technological advancements and strategies, such as leak detection, low-emission valve designs, and process optimization, that help reduce emissions. The guide includes case studies demonstrating successful emissions control measures and concludes with the significance of continued efforts in emissions control and the potential for industries to lead in sustainability.

2024.06.07

Liquefied Natural Gas (LNG) trade plays a crucial role in the global energy market, linking producers and consumers across continents and significantly influencing international energy dynamics. This article explores the geopolitical factors, market trends, and pricing dynamics shaping the global LNG market. It also highlights the key players, major trade routes, and strategic partnerships driving market growth, while providing insights into the future challenges and opportunities within the industry.

2024.05.31

The global LNG market is experiencing unprecedented growth, fueled by increasing demand, technological advancements, and evolving market dynamics. As the world's energy landscape transforms, new opportunities and investment prospects are emerging, reshaping the future of the LNG industry. This article delves into the key drivers of LNG market growth, explores investment opportunities, and highlights potential challenges facing stakeholders in this rapidly evolving ecosystem.

2024.05.24

Safety is paramount in LNG facilities, where complex operations and hazardous materials pose inherent risks. Advanced valve systems and effective maintenance plans play crucial roles in enhancing operational safety, mitigating risks, and safeguarding personnel, assets, and the environment.

2024.05.17

The article delves into the convergence of innovation and sustainability in the LNG industry, emphasizing the development of eco-friendly valve solutions. It explores how environmental concerns and regulatory pressures are driving the industry to adopt advanced technologies and sustainable practices to minimize environmental impact and enhance operational efficiency.

2024.05.10

Explore the complexities of the global LNG supply chain and the critical role of valves in ensuring seamless operations. Dive into the factors influencing valve selection and optimization across different stages of the LNG supply chain, from extraction to distribution. Gain insights into best practices and innovative solutions driving efficiency and reliability in LNG projects worldwide.

2024.05.03

Valves play a crucial role in industrial applications. However, when dealing with corrosive media, selecting the correct valve material is of paramount importance. This article delves into the key considerations for selecting valve materials for different corrosive media and provides practical guidelines for valve selection, installation, and maintenance.

2024.04.12

The article provides insights into commonly used valves in wastewater treatment, discussing types like gate, butterfly, ball, and check valves, along with installation principles and maintenance management. It emphasizes the critical role of proper valve selection, installation, and management for ensuring smooth and efficient wastewater treatment processes.

2024.04.03

The latest updates to API 6D, a vital standard in the oil and gas sector, reflect the industry's evolving needs and technological advancements. Released in November 2021, the 25th edition incorporates feedback from stakeholders to enhance valve standards. This article examines key revisions, including new requirements for bolts, actuators, and design validation, demonstrating a commitment to safety and excellence in valve technology worldwide.

2024.03.28

In the evolving energy landscape, hydrogen emerges as a prominent clean and renewable source. Advanced hydrogen pipelines and innovative valve technologies are essential for its safe and efficient application. This article explores the evolution of hydrogen valve technology and future trends in this field.

2024.03.22

In the realm of advancing energy technologies, hydrogen has emerged as a pivotal player for clean and efficient energy solutions. This article explores key considerations in the design and installation of hydrogen pipelines and valves, specifically focusing on valve selection, material specifications, and installation guidelines under high-temperature and high-pressure conditions. The objective is to offer practical insights for the sustainable development of hydrogen energy technology.

2024.03.15

In a world prioritizing energy and sustainability advancements, exploring hydrogen applications is no longer just a pursuit but a necessity. This series aims to offer a concise guide to the essential requirements and considerations for safely and efficiently handling hydrogen gas as we delve into the complexities of hydrogen pipelines and valves.

2024.03.08

In the dynamic realm of industrial applications, the demand for hydrogen-related technologies is surging, driven by the global shift towards sustainable and clean energy solutions. In this context, the article explores the critical requirements and challenges associated with hydrogen pipelines and valves, focusing on the properties of hydrogen and its impact on materials.

2024.02.23

In today's manufacturing landscape, cost efficiency is crucial. OEM casting stands out as a transformative solution, bringing substantial benefits through mass production, material savings, and streamlined processes. This exploration delves into the multifaceted advantages of OEM casting, showcasing its potential to revolutionize cost-effectiveness across industries.

2023.12.07

This article delves into common valve materials such as cast iron, carbon steel, and stainless steel. It elaborates on their characteristics, abbreviations, pressure resistance, temperature ranges, application areas, and prevalent standards, aiming to provide clear guidance for valve selection.

2023.11.23

When it comes to bolstering the corrosion resistance of stainless steel, especially in challenging environments like machining and fabrication, basic maintenance isn't always enough. Enter advanced treatments, and in this guide, we'll delve into one of the most effective techniques—passivation treatments.

2023.11.17

INOX-TEK Insights: Safeguarding Stainless Steel Against the Unseen Threat of Intergranular Corrosion

Intergranular corrosion, a hidden adversary to stainless steel, operates discreetly at the microscopic level, undermining the metal's structure without leaving visible surface clues.

2023.09.25

In the ever-evolving world of product manufacturing, quality control is paramount. Businesses understand the importance of ensuring that their products meet the highest standards before they hit the market. This is where valve certification comes into play. Whether it's faucets, industrial pipes, or medical equipment, valve certification ensures that a product meets specific industry standards and regulations, guaranteeing its quality, safety, and performance. By understanding the importance of valve certification and its impact on quality control, businesses can safeguard against potential liabilities, uphold their brand reputation, and meet customer expectations. In this article, we will delve deeper into the significance of valve certification and how it contributes to ensuring product excellence.

2023.09.04

To determine which valve wins the battle for efficiency and reliability, we'll examine factors such as flow control, seal performance, maintenance requirements, and cost. By understanding the strengths and weaknesses of each valve type, you can make an informed decision for your specific needs. So, let's dive into the battle between ball valves and gate valves and find out which one emerges as the winner in the world of industrial valves.

2023.08.10

When it comes to controlling the flow of liquids or gases in various industries, valves play a crucial role. A valve is a mechanical device designed to regulate, direct, or control the flow of fluids (liquids, gases, or even slurries) by opening, closing, or partially obstructing passages. Valves are essential components in a wide range of applications, ensuring efficient and precise management of fluid movement.

2023.08.04

As the world embraces the urgent need for sustainable energy solutions, the spotlight is shining brightly on Green Hydrogen - a clean and renewable energy source that has the potential to revolutionize the way we power our planet. In this blog post, we explore the key aspects of Green Hydrogen, its production, and its role in building a greener future.