Valve Type / Material

Total

21

2024.08.02

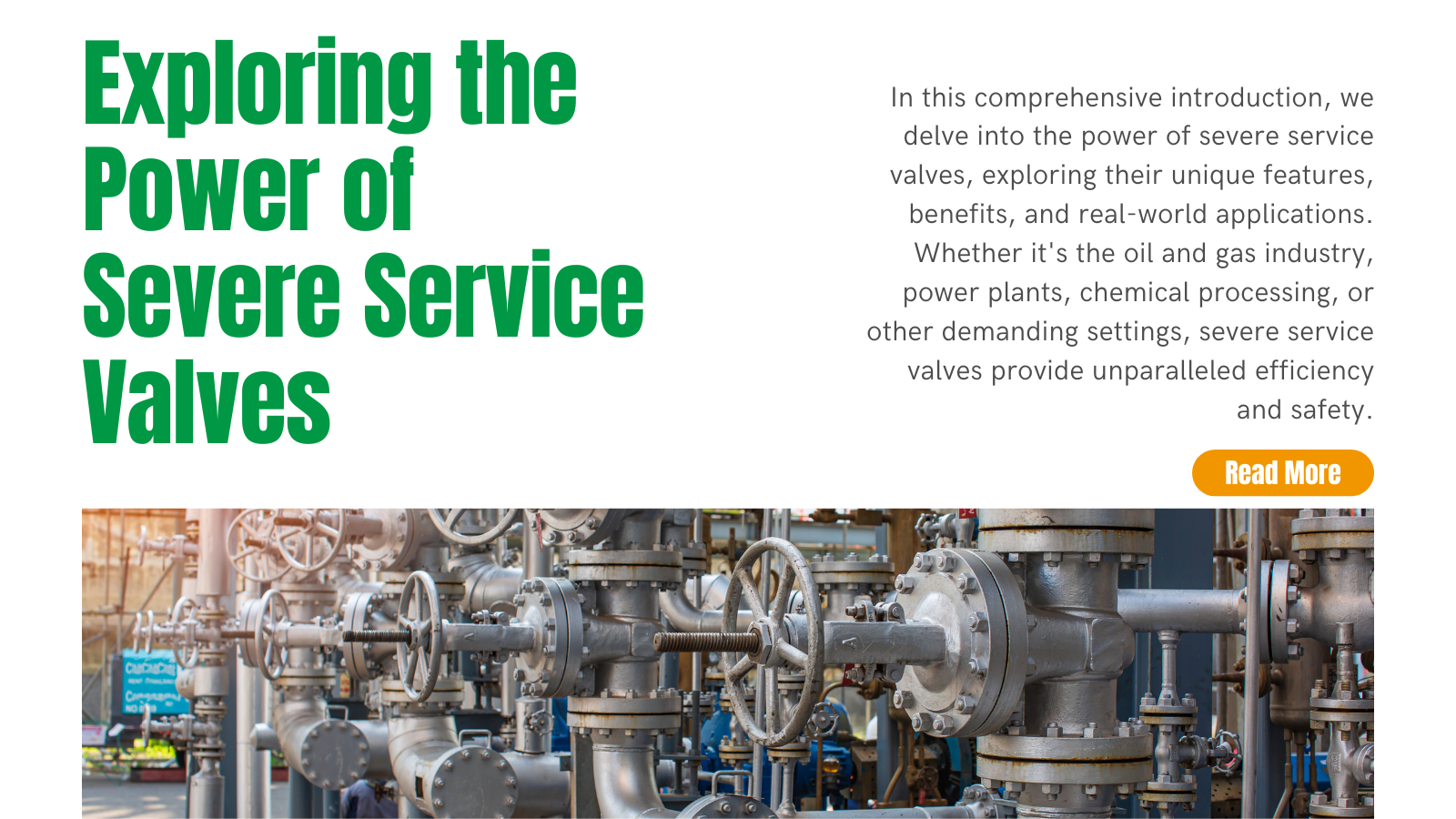

Severe service valves are essential components in various industries due to their ability to operate under extreme conditions such as high temperatures, high pressures, corrosive environments, and abrasive materials. These specialized valves ensure consistent performance, durability, and safety, making them vital in sectors like oil and gas, power generation, chemical processing, and mining. The article explores the unique features, benefits, and real-world applications of severe service valves, highlighting their importance in maintaining operational efficiency and safety. It also provides insights into key characteristics, types, and factors to consider when selecting these valves for specific applications.

2024.07.26

LNG (Liquefied Natural Gas) is primarily composed of methane. When natural gas is cooled to -162°C at atmospheric pressure, it transforms from a gaseous state into liquid form, known as LNG. One cubic meter of LNG is equivalent to 625 cubic meters of natural gas in its gaseous state at standard conditions. This significant volume reduction makes the storage and transportation of LNG more efficient and cost-effective.

2024.07.19

Cryogenic valves are critical for managing ultra-low temperature gases and liquids in various industries. Key considerations for selecting the right valve include temperature range, material selection, design, leakage prevention, and industry certifications. Making informed choices ensures safety, efficiency, and reliability in cryogenic operations.

2024.07.05

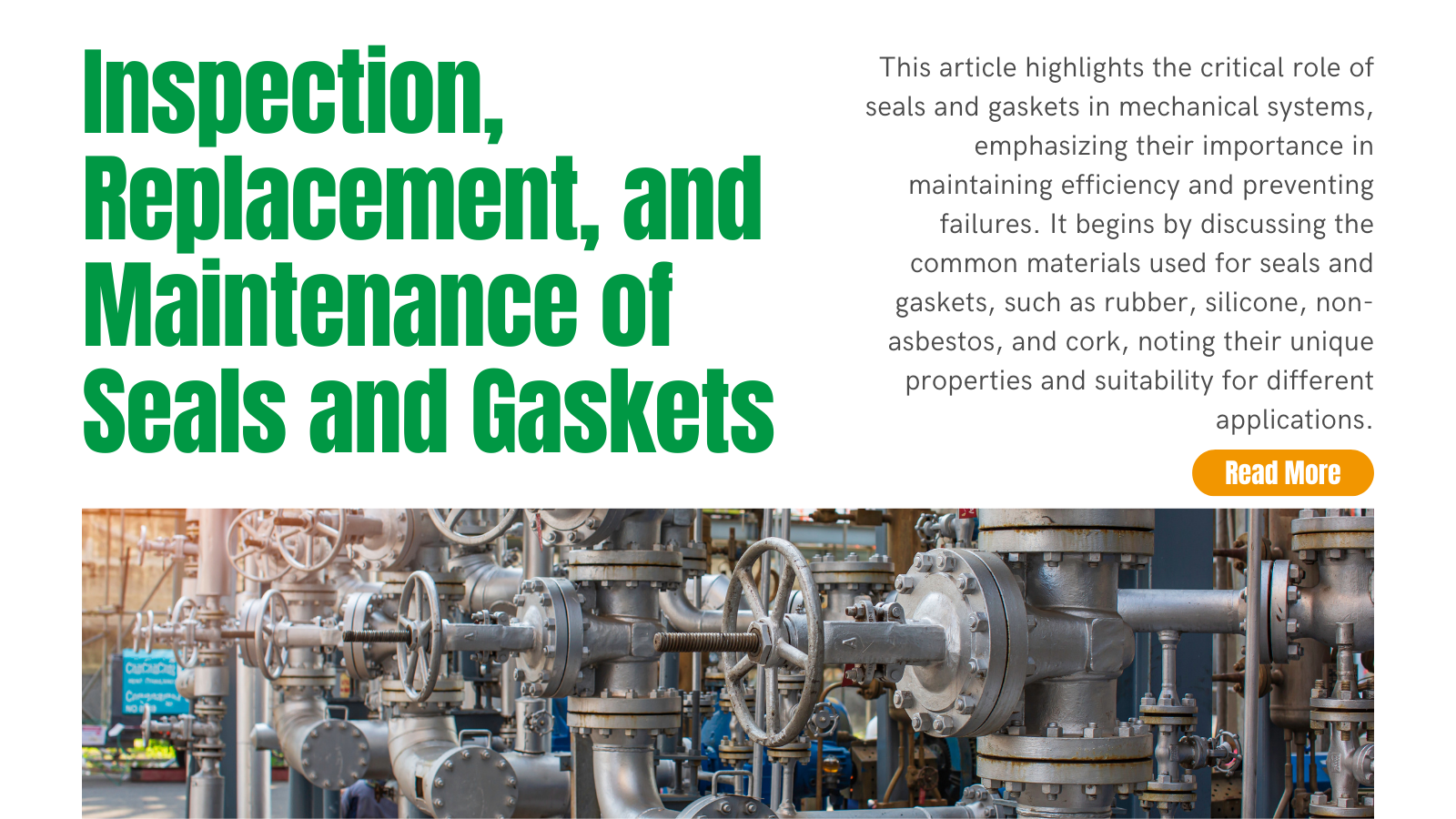

We underscores that diligent maintenance of seals and gaskets is essential for ensuring the longevity and optimal performance of mechanical systems. By following the outlined practices, operators can prevent costly repairs, improve system efficiency, and maintain reliable machinery operations.

2024.04.12

The article provides insights into commonly used valves in wastewater treatment, discussing types like gate, butterfly, ball, and check valves, along with installation principles and maintenance management. It emphasizes the critical role of proper valve selection, installation, and management for ensuring smooth and efficient wastewater treatment processes.

2024.03.28

In the evolving energy landscape, hydrogen emerges as a prominent clean and renewable source. Advanced hydrogen pipelines and innovative valve technologies are essential for its safe and efficient application. This article explores the evolution of hydrogen valve technology and future trends in this field.

2024.03.22

In the realm of advancing energy technologies, hydrogen has emerged as a pivotal player for clean and efficient energy solutions. This article explores key considerations in the design and installation of hydrogen pipelines and valves, specifically focusing on valve selection, material specifications, and installation guidelines under high-temperature and high-pressure conditions. The objective is to offer practical insights for the sustainable development of hydrogen energy technology.

2024.03.15

In a world prioritizing energy and sustainability advancements, exploring hydrogen applications is no longer just a pursuit but a necessity. This series aims to offer a concise guide to the essential requirements and considerations for safely and efficiently handling hydrogen gas as we delve into the complexities of hydrogen pipelines and valves.

2024.03.08

In the dynamic realm of industrial applications, the demand for hydrogen-related technologies is surging, driven by the global shift towards sustainable and clean energy solutions. In this context, the article explores the critical requirements and challenges associated with hydrogen pipelines and valves, focusing on the properties of hydrogen and its impact on materials.

2023.12.07

This article delves into common valve materials such as cast iron, carbon steel, and stainless steel. It elaborates on their characteristics, abbreviations, pressure resistance, temperature ranges, application areas, and prevalent standards, aiming to provide clear guidance for valve selection.

2023.11.23

When it comes to bolstering the corrosion resistance of stainless steel, especially in challenging environments like machining and fabrication, basic maintenance isn't always enough. Enter advanced treatments, and in this guide, we'll delve into one of the most effective techniques—passivation treatments.