INOX-TEK Insights: Safeguarding Stainless Steel Against the Unseen Threat of Intergranular Corrosion

Decoding the Stealthy Culprit: Intergranular Corrosion Unveiled

Intergranular corrosion, a hidden adversary to stainless steel, operates discreetly at the microscopic level, undermining the metal's structure without leaving visible surface clues. Our exploration navigates the complexities of this phenomenon, shedding light on its occurrence, impact, and strategies to thwart or minimize its effects.

Revealing the Microscopic Battlefield

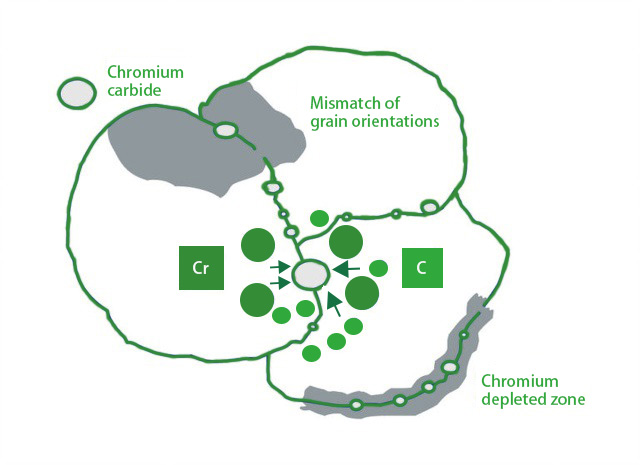

Stainless steel, a mosaic of crystalline grains, encounters vulnerability at grain boundaries in the form of intergranular corrosion. This subtle yet destructive process manifests in molecular-level damage, leading to consequences like cracking, loss of grain cohesion, and compromised structural integrity. Vigilant measures become imperative to address this covert menace.

<

<

Identifying the Culprit: Triggers of Intergranular Corrosion

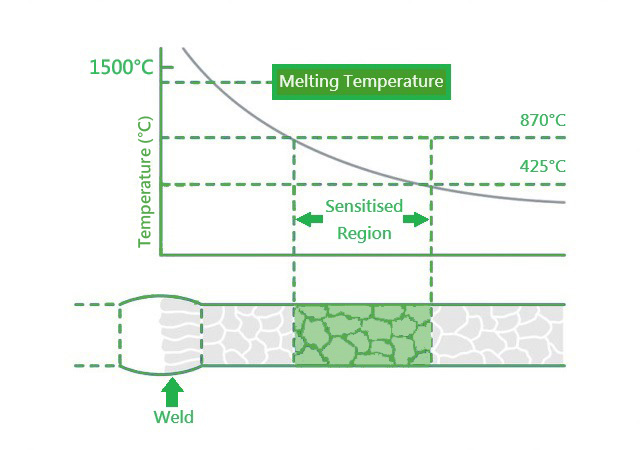

Intergranular corrosion sets its stage at temperatures ranging between 425°C and 870°C (887°F to 1598°F), commonly witnessed during welding, heat treatment, or in high-temperature environments. Elevated temperatures induce structural alterations, where chromium reacts with carbon, forming chromium carbide near grain boundaries. This sparks the formation of anodic and cathodic cells, initiating the intergranular corrosion process.

Strategies to Fortify Against Intergranular Corrosion

A proactive approach to material selection stands as the cornerstone for sustained safety and performance. Opting for low-carbon alloys (identified with an 'L') showcases superior resistance to intergranular corrosion. Alternatively, alloys infused with titanium or niobium present robust protective qualities. However, a note of caution surfaces regarding a nuanced form of intergranular corrosion known as knife-line attack, relevant to alloys with added titanium or niobium.

Effective Reversal Techniques

In certain scenarios, resorting to solution-annealing emerges as a viable option. This process involves subjecting the metal to temperatures ranging between 1,060°C and 1,120°C (1940°F and 2048°F), followed by swift water quenching. While proven effective, this method encounters limitations in treating extensive assemblies and lacks future damage protection during welding or subsequent repairs.

Guidance from Industry Standards and Certifications

Dependable benchmarks such as ASTM International's A262-15 and A763-15 play a pivotal role in evaluating susceptibility to intergranular attack. These standards ensure rigorous testing, validating adherence to quality benchmarks and fortifying your choice of stainless steel against potential corrosion challenges.

INOX-TEK: Partnering in Stainless Steel Solutions

INOX-TEK, with over decades of expertise, stands ready to assist industries in worldwide. Our extensive selection of stainless steel products, including piping, tubing, flanges, and fittings, we can ensures tailored solutions for your industry needs. Contact us today to embark on a corrosion-resistant journey.

References

SANDVIK, University of New South Wales Sydney School of Materials Science and Engineering, CD Corrosion, Nitty Gritty, Wikipedia, Corrosionpedia, ScienceDirect, National Association of Corrosion Engineers International, Corrosion Doctors, Specialty Steel Industry of North America (SSINA), Fractory, Swagelok, unifiedalloys.